Technical Data

The MAXICOOL® copper coolers can safely and continuously operate at heat fluxes as high as 500 kW/m2. It has been successfully implemented in Ni and Cu slag cleaning furnaces, platinum group metals smelting furnaces, autocatalyst recycling furnaces, and top submerged lance furnaces. Refer to the key references section as well as our library of papers.

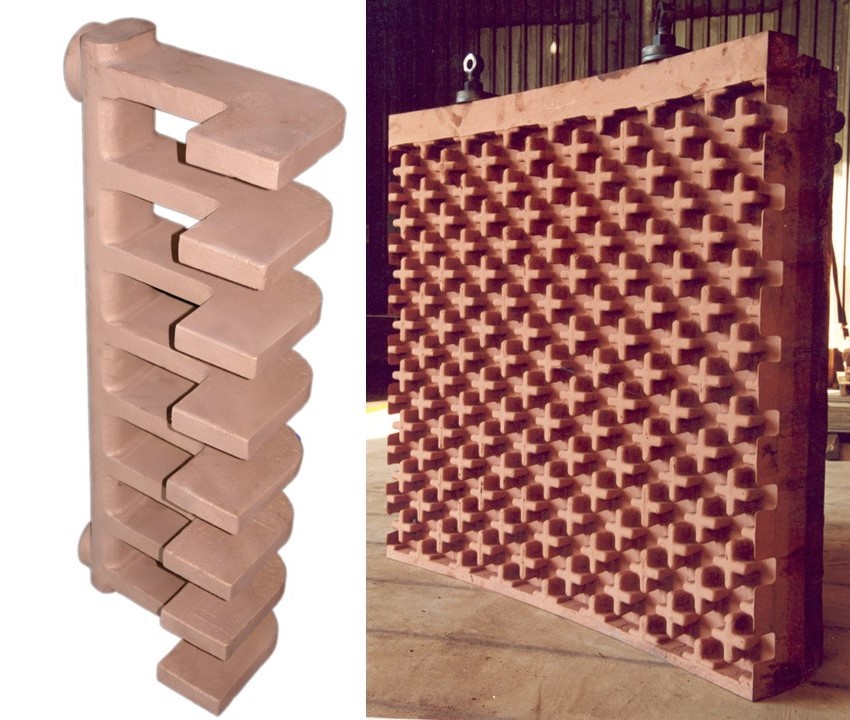

The SAFECOOL® or copper plate cooler cooling systems are employed in situations where the hot face heat flux is limited to below 150 kW/m2, and where it is important to keep the cooling water channels external to the furnace shell. These copper elements are normally embedded in the sidewall refractory lining. A novel design combining copper and graphite has been developed for applications where liable sulphur can lead to corrosion of the copper elements.