Safety

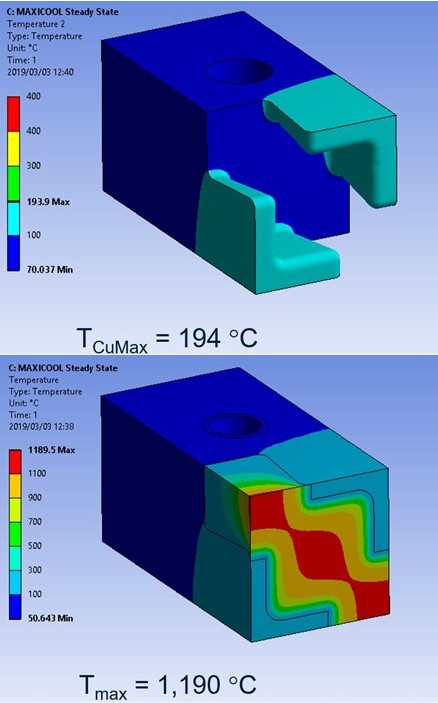

Our copper cooling elements are designed to maintain the maximum copper temperature below 400°C when subjected to extreme operating conditions. This is to ensure that the structural integrity of the copper cooling elements is maintained and to prevent oxidation of the copper over time.

Cast-in Monel tubes in the MAXICOOL® copper coolers eliminate the risk of water leaks caused by casting defects. Long-term cracks in the copper due to thermal fatigue are unlikely to extend into Monel passages. The cooling water circuits in our COPPER-GRAPHITE COMPOSITE coolers are kept external to the furnace shell to prevent any leaks inside the furnace.

Tenova has developed an alternative cooling system called MEGtec™ for critical deep-cooled applications such as alloy and matte tapholes. MEGtec™ uses a cooling medium that is unlikely to cause explosions when it comes in contact with molten matte or alloys.