Innovation

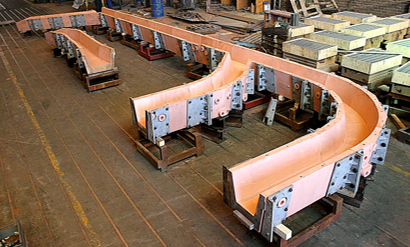

Our copper launders are designed for receiving the tapped products from copper smelting furnaces. By removing the heat from the passing flow at a high rate, the surface temperature of the copper is kept below temperatures that result in launder damage and a freeze lining of process material is formed and maintained to protect the launder.

Our copper launders do not have any water channels under the molten flow, whilst still effectively removing the heat from the bottom of the launder through the sidewall cooling channels. Therefore, on those occasions where damage occurs, there is a greatly reduced risk of explosions. An innovative and patented pocket system incorporated in the bottom of the launders acts like a fuse, ensuring any molten metal or slag will bypass the cooling water channels during damage. In addition, since the water channels are not damaged, the launder can be repaired and reused. The pocket system is designed to increase the stiffness of the launder segment and prevent deformation due to thermal cycling.

Tenova Pyromet designs and produces copper launders of various lengths with either drilled water passages or cast-in pipes.