iTAP

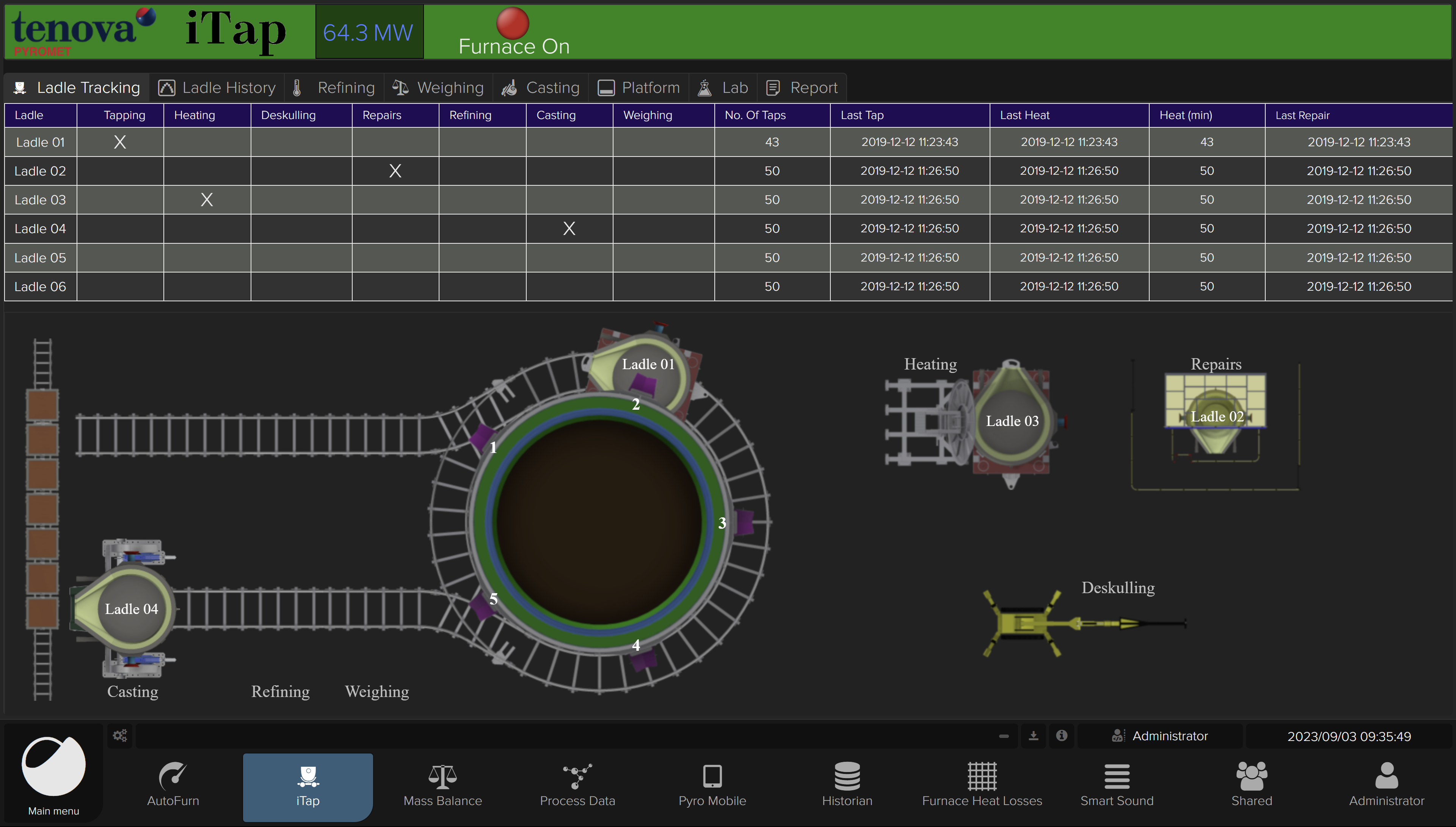

iTap is a sophisticated system for tracking furnace taps and managing product quality by integrating chemical composition data into the furnace information system. It plays a critical role in refining processes and ensuring consistent product quality.

Key Features:

- Ladle Tracking: Using advanced video feeds and QR codes, iTap accurately tracks ladles throughout the tapping process, ensuring precise product identification and traceability.

- Real-Time Data Capture: The system captures data directly from the tapping platform, allowing for real-time analysis and decision-making.

- Sample Management: iTap oversees the entire sample management process, from tapping to lab analysis, ensuring the reliability of the product's chemical composition data.

- Integration with Process Control: By incorporating chemical composition data into the overall process control system, iTap helps optimize furnace operations and improve final product quality.