Technical Data

The Tenova Slag Cleaning Furnace (SCF) is designed for versatility, capable of adapting to various operational demands across different smelting applications. Key technical highlights include:

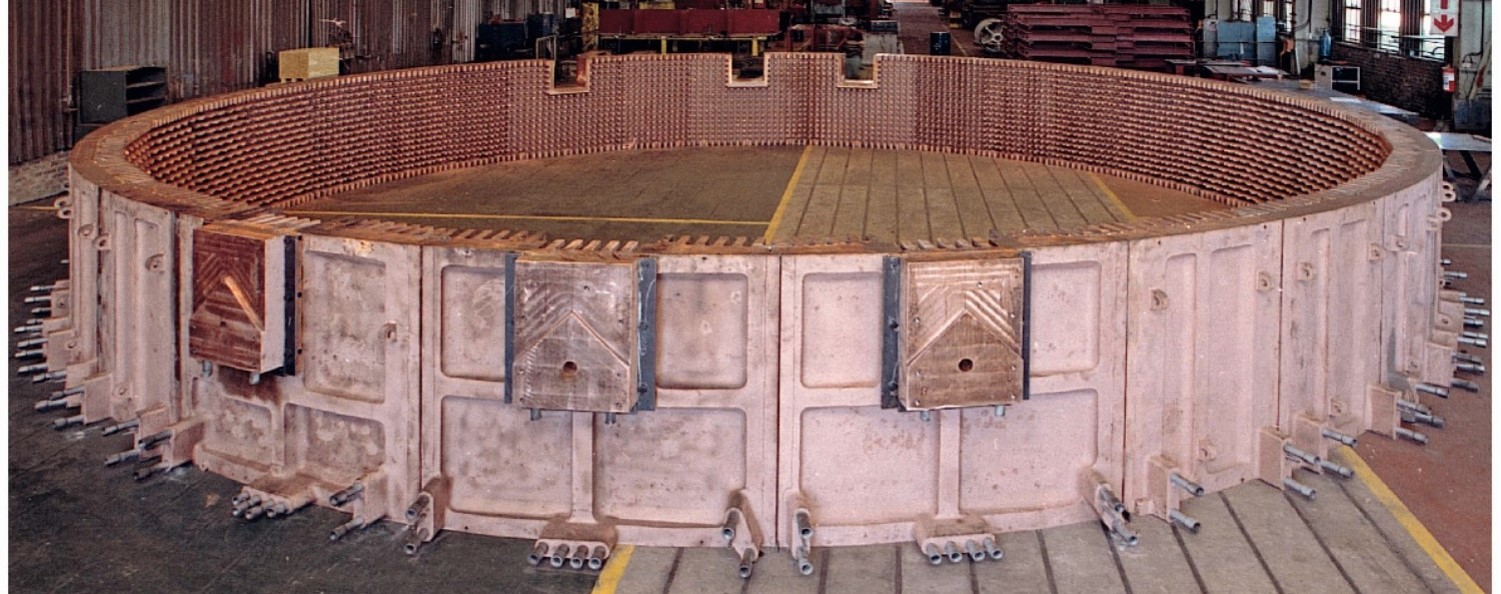

Furnace Design: Rectangular or circular geometry optimized for handling large slag volumes with robust thermal expansion management.

Electrode Configuration: Söderberg or graphite electrode designs, arranged in 6-in-line, single or multi-delta configurations, to suit diverse power requirements and slag cleaning requirements.

Furnace Containment: Advanced lining/cooling system designs to provide exceptional thermal stability and wear resistance, extending furnace life, and limiting heat losses.

Customizable Power Inputs: Flexible power configurations to match project-specific needs, ensuring operational efficiency under varying conditions.