Skip to main content

- MEGtec™ can replace water cooling on existing copper cooling elements, such as deep-cooled metal, matte and slag taphole blocks, and high-intensity sidewall coolers.

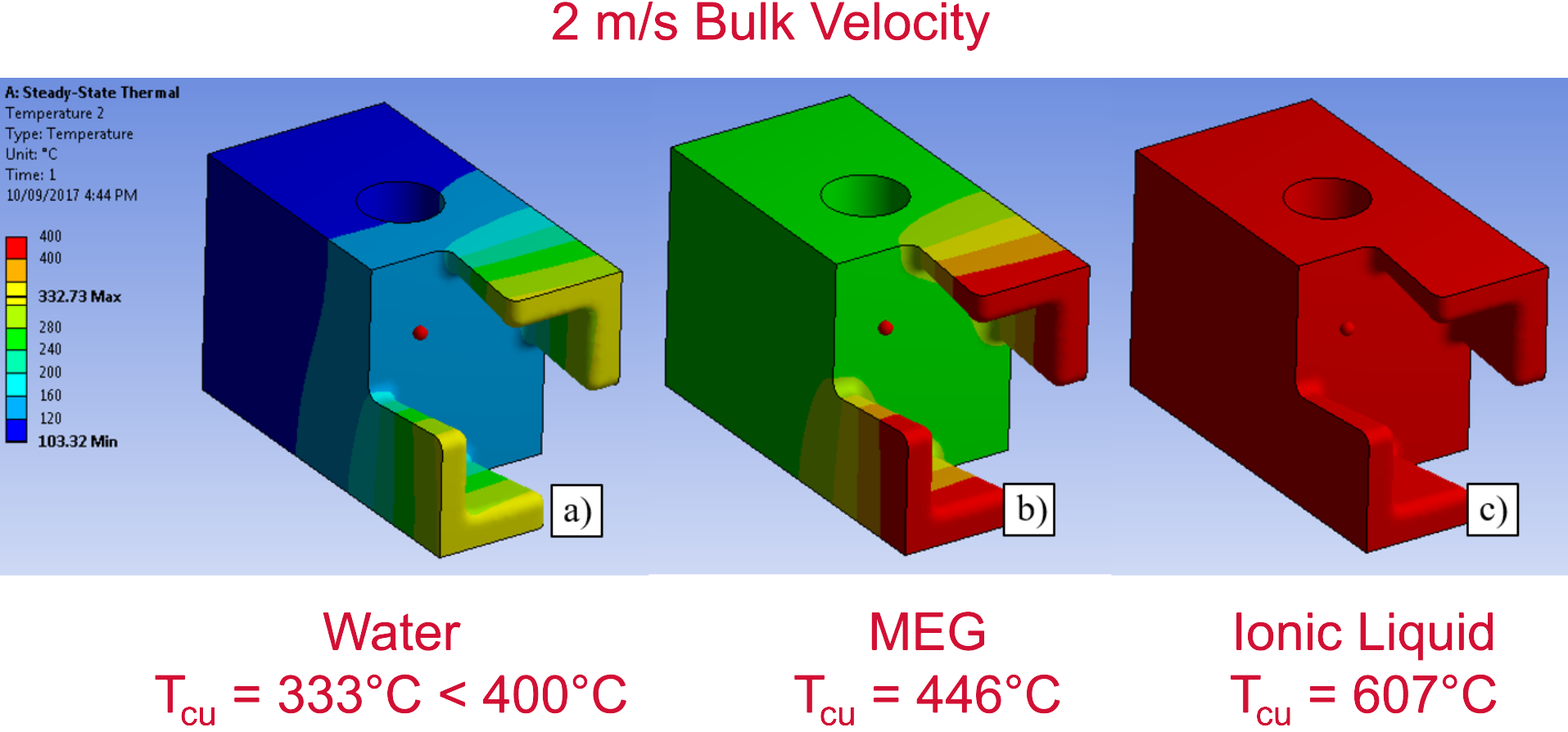

- Employs a mono-ethylene glycol (MEG)-based coolant mixture for enhanced safety and performance.

- Designed for high thermal efficiency to reduce taphole wear, stabilise furnace refractory linings, and maintain a competent slag freeze-lining.

- Operates safely under extreme furnace operating conditions.

- MEG-based coolant significantly reduces the explosion risk compared to traditional water cooling.

- Supports higher coolant flow rates for improved heat removal without compromising the existing piping system integrity.

- Incorporates an optimised and modular pumping and reticulation system design for easy conversion.

- Ideal for use in critical high-wear zones such as slag areas and taphole cooling blocks.

- Proven solution for increasing furnace operational intensity and campaign life while improving safety.

- Environmentally friendly coolant with low toxicity and corrosion inhibitors and biodegradable properties.