Innovation

Tenova Pyromet’s MEGtec™ system introduces a safer approach to furnace cooling by replacing traditional water with a mono-ethylene glycol (MEG)-based coolant. While water offers good thermal performance, it poses a serious explosion risk if leaks occur near molten metal or matte. MEGtec™ addresses this critical safety concern without compromising heat transfer capability.

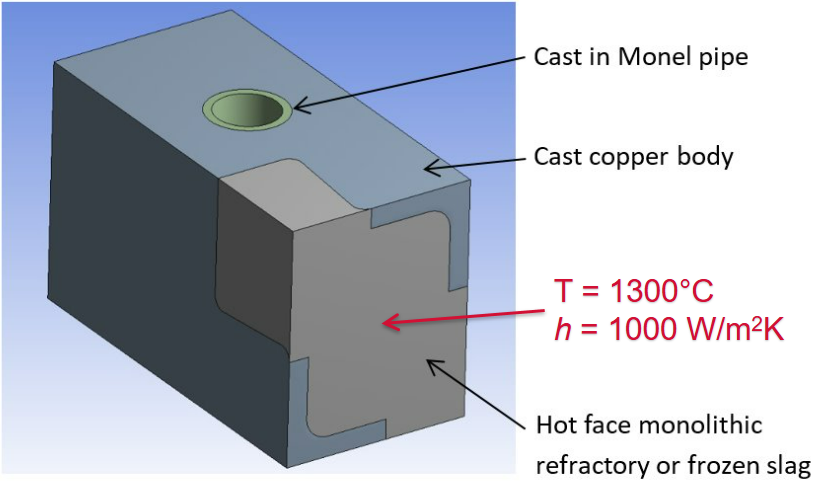

The system combines Tenova’s precision-engineered copper cooling elements with MEG-based coolant to create a stable, high-performance solution for demanding furnace environments. It supports higher operating temperatures, protects refractory linings, and enables longer furnace campaigns.

What sets MEGtec™ apart is not just the coolant, it’s the complete engineered system. Tenova works closely with each customer to tailor the MEGtec™ system to their specific furnace design, critical cooled areas, and process conditions. This ensures effective cooling with a significantly lower risk profile. The MEGtec™ system comes in modules for easy installation and integration with existing cooling elements and systems.

MEGtec™ reflects Tenova’s commitment to practical innovation: safer, smarter, cost-effective, and ready for the increasing demands of modern smelters.