Technical data

Tenova is able to assist its customers in the entire offer and design phase of the plant, providing a service that translates into a tailor made configuration with respect to the specific needs of each case.

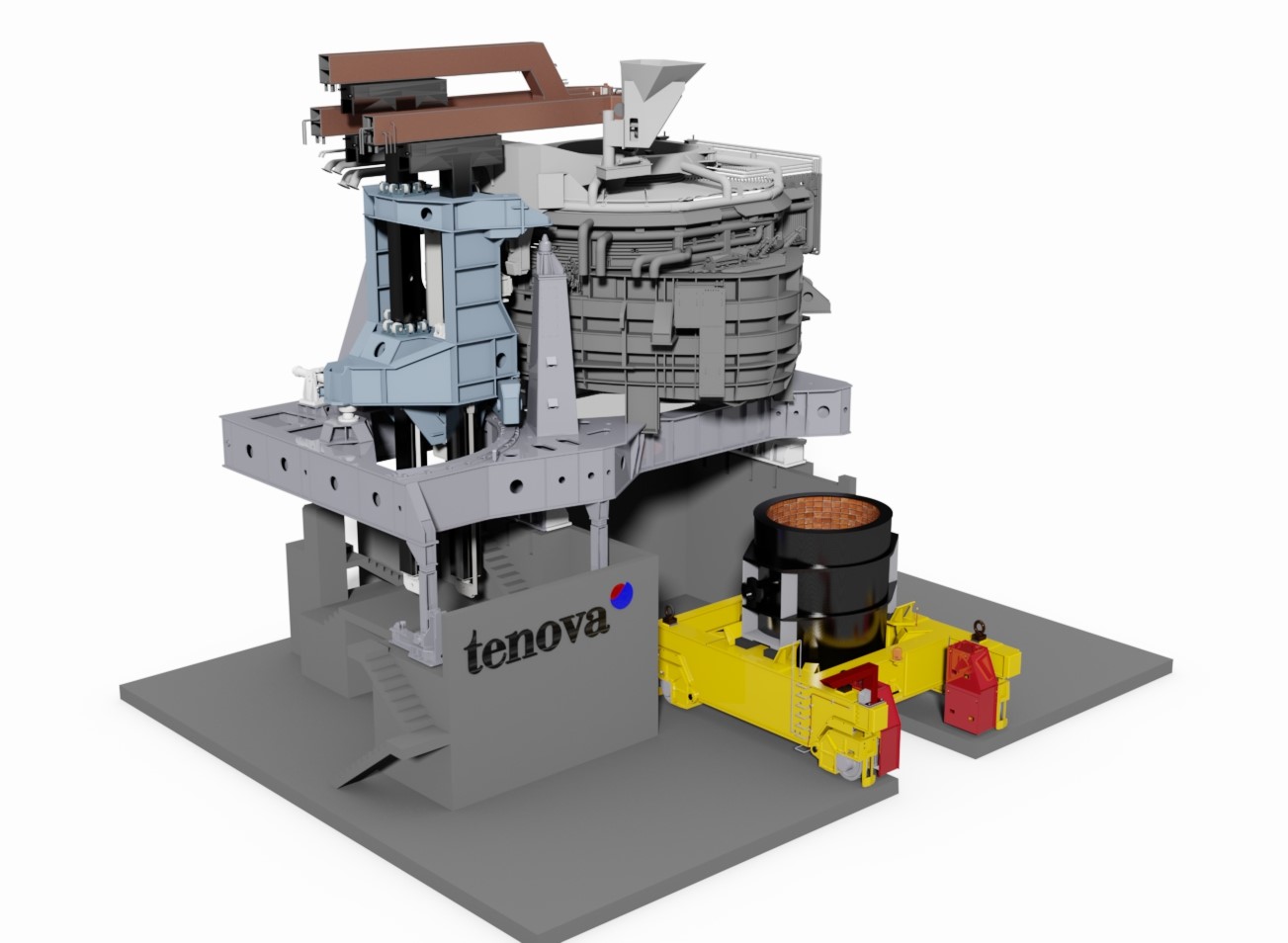

EQUIPMENT & CONFIGURATION

- AC/ DC type furnace

- 5 to 300 and more tons heat size

- 5 to 420 tons per hour productivity

- Full platform / half platform design

- Many layout variants available, to fit different melt shop reality

PROCESS & OPERATION

In Tenova's EAF process, charge materials are top-charged by buckets and melt, in the first stage, by direct energy transfer from the electric arcs and then in the refining and superheating phases by melting by immersion in the liquid bath. The Tenova’s EAF is designed to optimize all the phases of the melting process, allowing to gain the best energy efficiency and the productivity of the melting unit.

- Ultra High Power electric energy supply

- Ultra High Power chemical energy supply

- High flexibility in metallic charge mix (scrap, pig iron, hot metal, HBI/DRI, scrap surrogates, skulls)

- Scrap Tracking System for better control the raw material input

- High melting efficiency

- Low OPEX

- Exceptional reliability: >98% on the whole unit

REFERENCE

Among other references, Tenova is proud to have designed and supplied the most productive DRI-based furnace in the World at Tosyali Iron Steel Industry Algerie SPA.