Digital

Digital technologies are changing our world, including the way we make steel. Using technologies like predictive maintenance, industrial Internet of things (IIoT), cloud platforms, augmented reality and artificial intelligence, through a data-driven approach, you can now gain insights into your plant, improve your decision making and optimize your production process.

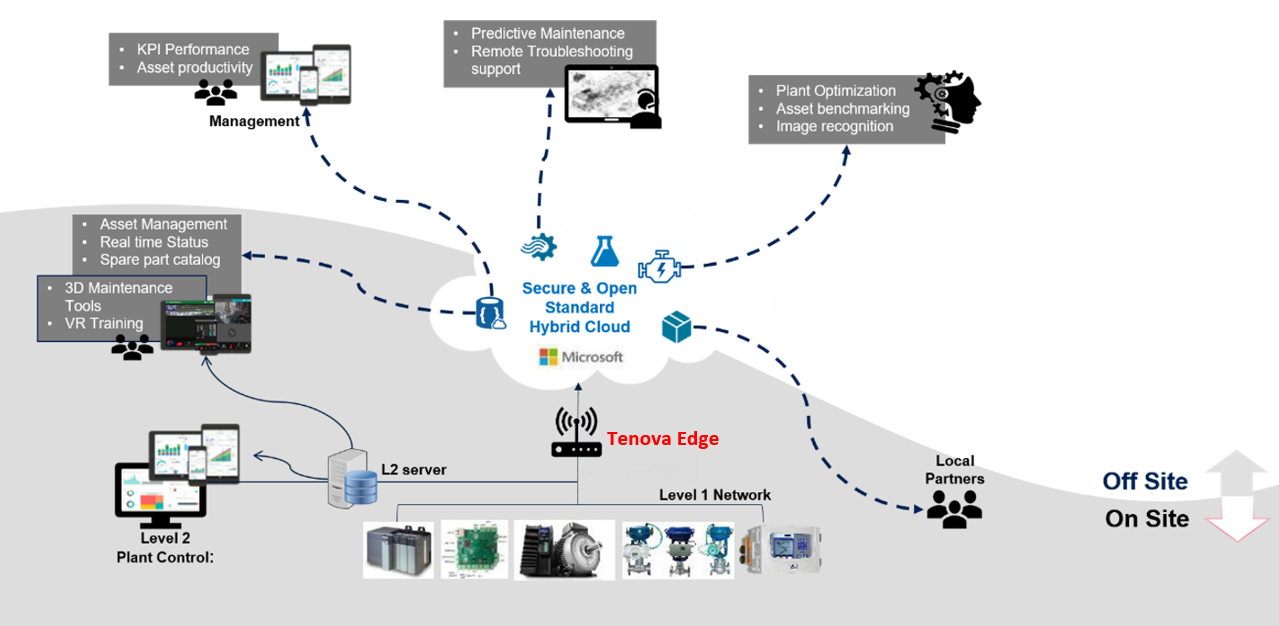

Tenova is able to provide you with the ultimate technologies in this field to cover a huge variety of applications as you can see in the image below.

With the purpose of making easier the access to these innovations, Tenova has decided to propose them into modular digital packages, each of them focusing on a specific aspect.

These modules can be composed and customized to help you reach your goals.

The target of such solutions is the activation of an overall process of digital transformation in the steel production processes, enabling:

- Staff safety;

- Increase of production efficiency which results in lower OPEX and lower consumption of resources (hence a more environmental conscious production).

- Higher production flexibility;

- Improved planning and optimization of maintenance activities Quicker (and in some cases immediate) response with regards to the services provided;

- Quality and personalization of products;

- Transparency, traceability and sustainability of production processes;

- Staff training.