Technical data

Tenova is able to assist its customers in the entire offer and design phase of the plant, providing a service that translates into a tailor made configuration with respect to the specific needs of each case.

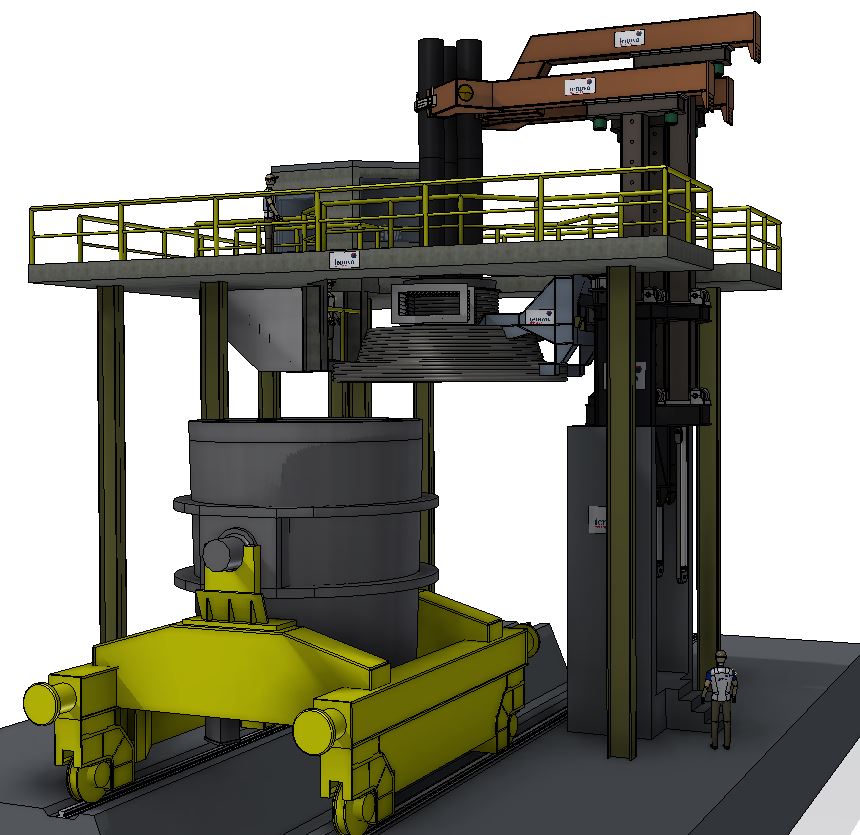

EQUIPMENT & CONFIGURATION

- AC-type electric energy configuration

- Single of twin type configuration

- Trimming station configuration (LF without heating equipment)

- 5 to 350 and more tons heat size

- Up to 6°C/min heating rate

- Single-point / multi-points roof lifting

- Standard, hybrid and controlled atmosphere roof

- Ferroalloys injection, wire injection

- Emergency lance

- Temperature & Sampling manipulator / robot

- Many layout variants available, to fit different melt shop reality

PROCESS & OPERATION

Improving steel temperature and analysis control is a key aspect of the secondary metallurgy processes. Tenova Ladle Furnaces enable precise control of the melt temperature and of the chemical composition to guarantee improvement of productivity, flexibility and quality.

- Low OPEX

- Exceptional reliability: >98% on the whole unit