Automation

More and more in modern electric steel mills a role of strategic importance is assumed by the operational and management coordination between the different production phases.

This need becomes more evident where synchronization between the various phases must always be guaranteed. Tenova automation systems are conceived and designed with the aim of guiding the operator through each phase of the production process, providing reliable and comprehensive decision-making support, especially where the normal production flow is modified by unforeseeable causes.

The set of Innovative Technologies implemented in Tenova's automation systems, guarantee steel production by eliminating the presence of the operator inside risky areas, bringing the necessary inspection and control operations in remote and eliminating the direct interaction of man with the machine, guaranteeing the strictest safety conditions.

This, by applying solutions aimed at improving production/maintenance aspects, i.e. improving the continuity of operation of the plants, their productivity and troubleshooting assistance.

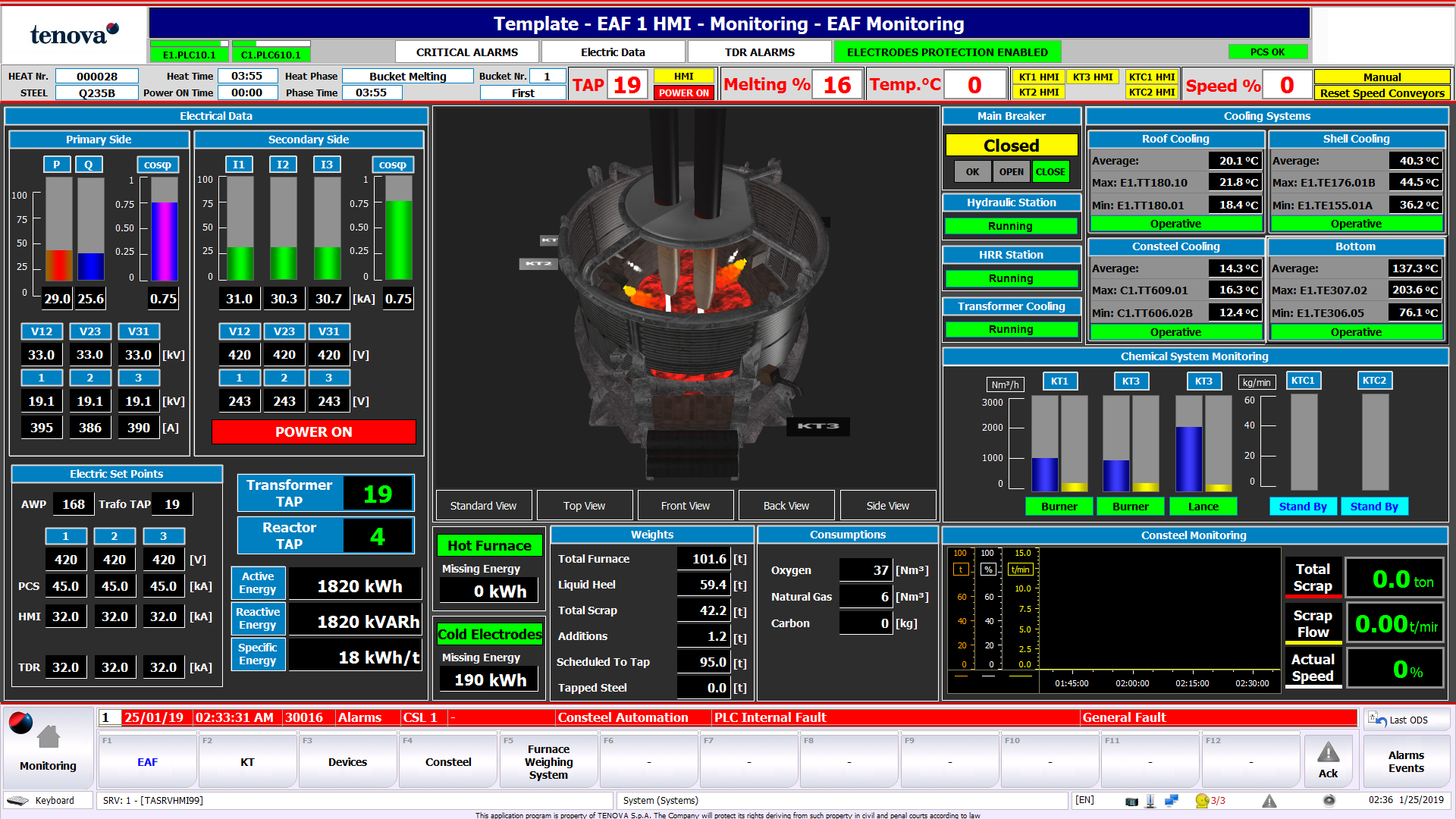

Tenova Automation suite assure the best and easy way to control the EAF thanks to the latest state-of-the-art Automation and Process Control systems, including the innovative TENOVA iMeltShop concept for the integrated control of the whole melt shop production line.

All the operations can remotely managed thanks to the possible close control room design and all technological packages included in TENOVA No-One-On-The-Floor: Temperature and sampling Robot with Polyeye for EAF internal visual check, Tenova Auto Tapping system, Scrap basket automatic charging system.