Innovation

BLUEdrivenTM Technology

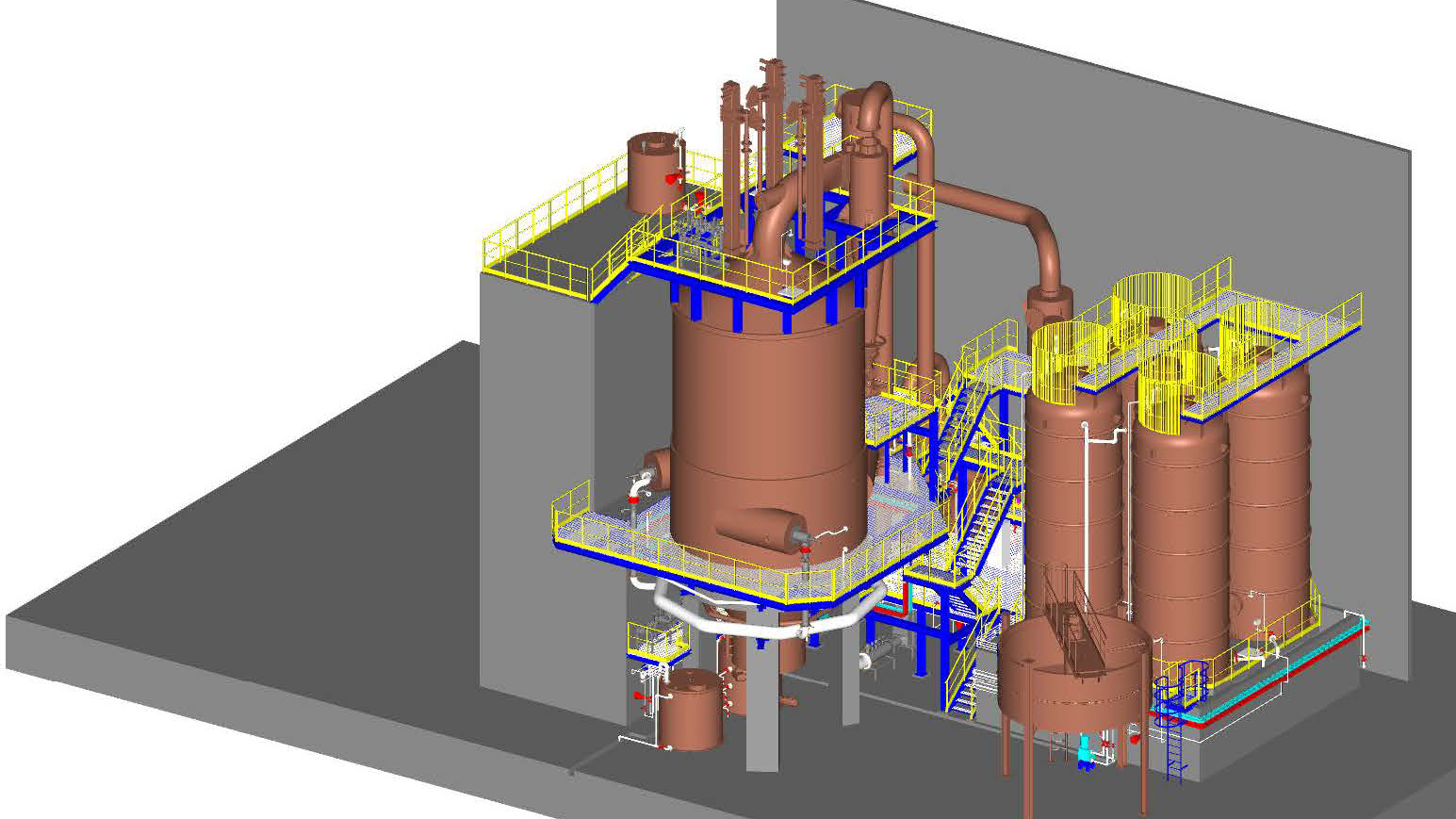

![]() BLUEdrivenTM Pyrolysis

BLUEdrivenTM Pyrolysis

set parameters to produce high quality Fe-oxide. Here it is decided whether the by-product creates revenues or solely costs. The system is a significant improvement in the flexible configuration of nozzles while at the same time enhancing the safety of work at the reactor head is achieved.

![]() BLUEdrivenTM Liquid Treatment

BLUEdrivenTM Liquid Treatment

is a long-term proven maintenance-free Venturi system with special nozzle-free inlet concept. In combination with a new designed liquid distributor, which enables maintenance outside the columns, a positive effect on the safety of the personnel and efficiency of the process plant.

![]() BLUEdrivenTM Emission Control

BLUEdrivenTM Emission Control

allows the operators to bring the plant in compliance with strict emission values. The reduction of the environmental pollution is possible due to closed circuits in exhaust gas cleaning section and reduce OPEX at the same time. There are no effluents and chemical treatment foreseen.

![]() ZEROwaste Process

ZEROwaste Process

fully recycles the rinse and scrubber water and allow the chlorides to flow back into the production cycle. An increase in plant efficiency of just 0.5% will bring the operators a 50% saving in fresh acid consumption.

![]() BLUEdrivenTM Flex Capacity

BLUEdrivenTM Flex Capacity

includes an integrated capacity increase of up to 50%. It is a worldwide unique capacity flexibility of an ARP allows adjustments of steel production according the demands while the operation remains uninterrupted and stable. Highlight: Lower capacity consumes direct proportionally less utilities.