Innovation

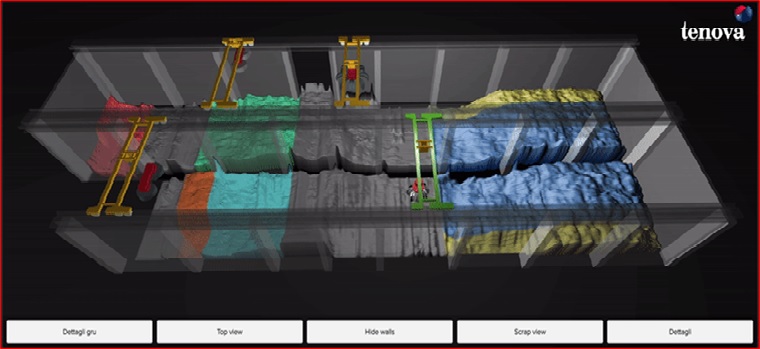

Laser Scanners for scanning the surface of the scrap yard. In this way it’s possible obtain the 3D reconstruction of the shape of the materials present in the entire scrap yard.

The data acquired are pre-elaborate from the PC on board and sent to the ground server where iSYM is able to calculate the VOLUME and, by material density information, the WEIGHT of the scrap material stored in the scrap yard itself.

iSYM allows to accurately trace the path that the individual deliveries of materials make from their entry into the plant to the ladle ready to be sent to the continuous casting.

It is therefore able to carry out statistical analyzes on the data thus acquired and, by reconstructing the path of the materials backwards, to obtain the correlation between the chemical analysis of the liquid steel produced and the ferrous materials used for the production of that specific lot.

In this way it is possible to correlate the presence of polluting elements, such as copper, nickel, arsenic, ... with the suppliers of the materials used for the production of the batch in question.