Automation

For every heat and for every bucket to load in EAF furnace the EAF process Control System (or Level 2 system) generate the scrap mix recipe.

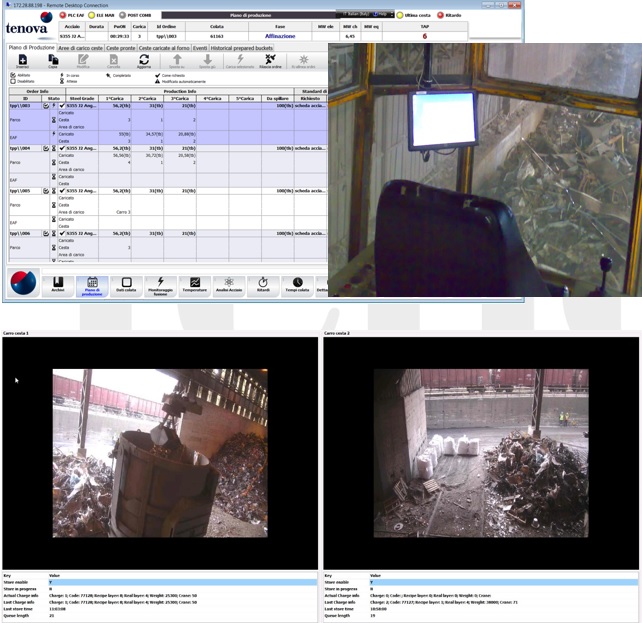

By the operator panel, installed in every cranes, the operator automatically receives the detailed scrap mix recipe in the form of a list of instructions for the construction of the scrap basket.

The system is able to automatically recognize all cranes command and/or operation and, always automatically, confirm the quality of the material charged in bucket. Of course, in case of needs (for example if the scrap quality foreseen in the recipe is no longer available), the operator has the possibility to manual declare a scrap quality different from what present in the recipe.

By the weighing system mounted on bucket car or at cranes hook, the system automatically receive the quantity of material charged in the bucket and, in real time, goes to fill the bucket charge report, for every heat and every bucket number.

At the end of bucket charge sequence, the feedback of the material (in quantity and quality) really charged in the bucked is send back to the EAF Process Control System; in this way the Level2 system is able to calculate and up-grade the electrical and chemical EAF melting profile, based on the real scrap materials charged in the EAF.

In case of scrap yard area divided in differ bays and in every if these bay is stored a different quality of scarp material quality, this bays organization is managed by the system. The iSYM, automatically, by cranes hook position, is able to recall the scrap quality managed by the cranes and charged in the bucket.

Not only… With all information related to quantity and quality of the scarp material handled and charged in EAF, the system is able to calculates:

- Estimation of residual stock in the park.

- The Cost analysis.

- Automatic recognition of the material gripping and unloading position.

- Automatic recognition of the basket in use.

- Registration of all bridge wagon movements (for mainatenance for example).

- Linking of the bridge wagon movement history to backet number and heat number.