Innovation

Constant investment in the latest technology makes Pomini's machines the cutting edge of the industry worldwide, providing customers with many modern functions, just a few of which are briefly mentioned here.

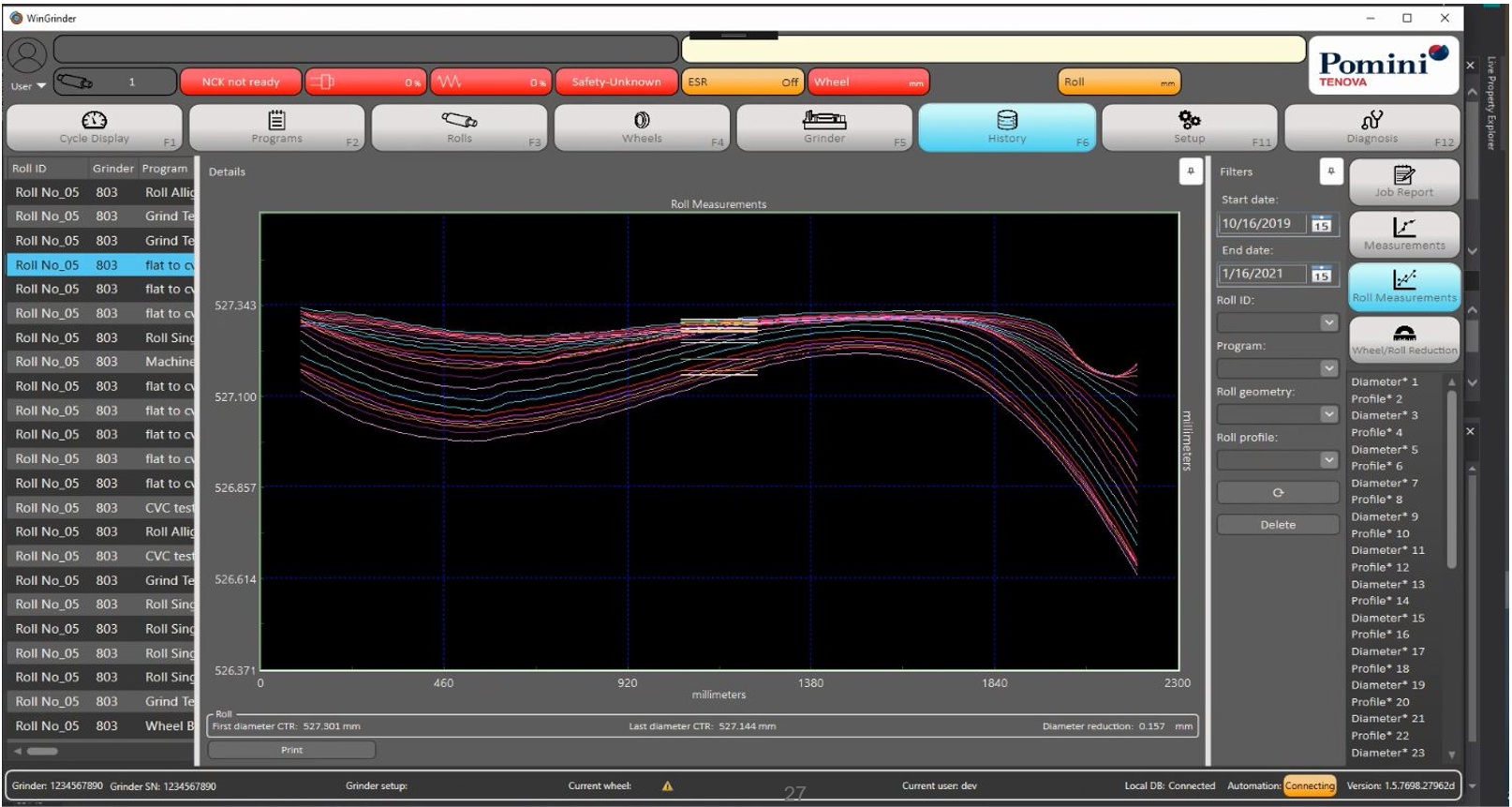

User Friendly HMI & extreme programming flexibility: rotational speeds programmable, fixed, sinusoidal, triangular or square wave; infeed and axis linear speed programmable; Inspektor system operating during grinding cycle; Profile measure any time.

Advanced Options: Load Control (kW or A) and algoritm with PID regulator; Short stroke also with caliper measure; Automatic profile generation or change (flat to CVC); Continuous Profile Compensation;

The most accurate data: profile up to 1000 sample, roundness measure 360 points (every degree), new interpolation algorithms.

Pomini Inspektor System: the complete, state of the art roll defect detection and vibration analysis system, sold in several hundred of systems worldwide, either as integral components of Pomini Tenova grinding machines or on competitor machines.

Pomini Tenova has a complete portfolio of both machines either foundation-free or with foundation block, so to always offer technical solutions optimized according to customer's actual working conditions, without compromise.