Safety & Automation

Safety

The Roll Grinders are designed so to ensure the highest level of safety for operators, according to the highest industry standards: during the automatic work cycle: processes are controlled by SIEMENS' SAFETY INTEGRATED technology, safety interlocks for safety fences are standardly included in the scope of the supply.

Automation

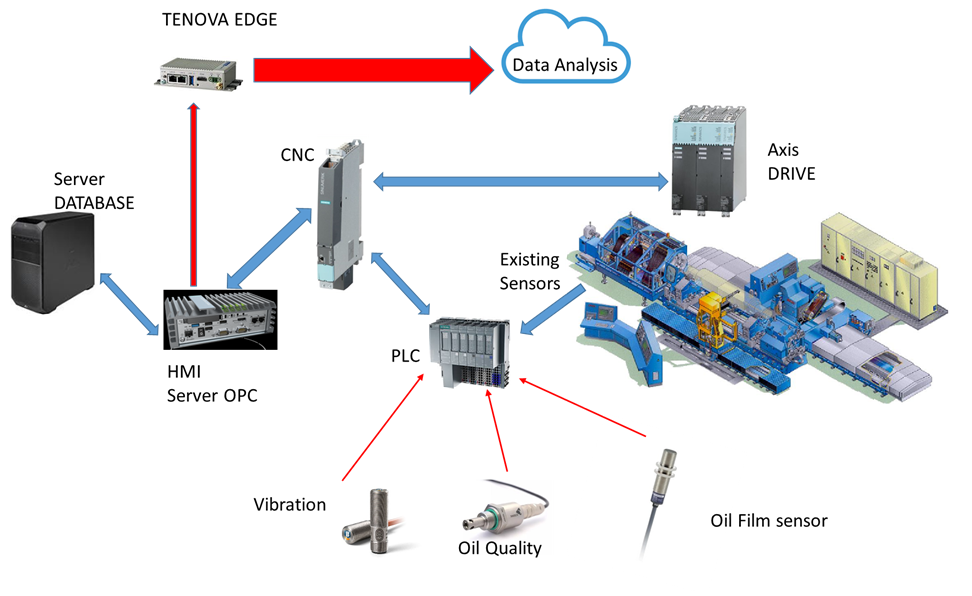

The use of the Total Integrated Automation platform (Siemens TIA Portal) allows to program both the PLC and the CNC in an optimized way since all the HW components (including the Drives and the PLC periphery) are interconnected and can be recognized within the Automation network with PROFINET technology.

During the execution of the grinding cycle, the operator can follow the progress of the process parameters through a dashboard where the working parameters and results are represented. Work and process data are used to define the machine's performance and to optimize the processing cycle itself, to establish the quality of the tools and the necessary maintenance conditions.

The data remain available in the database, which records the useful information both to certify the quality of the roll (profiles, tolerances, surface parameters, etc.) and to the conditions of the machine (power used, consumption of materials, adjustments and compensations, temperatures and operating conditions of the connected devices).