Technical data

Reliable [C] & Temperature Endpoint control for Low Carbon Grades; by eliminating assumptions and statistical models, Tenova’s M&E Balance approach is capable of predicting endpoint carbon to within 0.01% and temperature within 17 °C on about 90% of low carbon heats thereby generating significant operating cost benefits. Typically, low carbon heat savings range from $1.00 - $1.25 per tls.

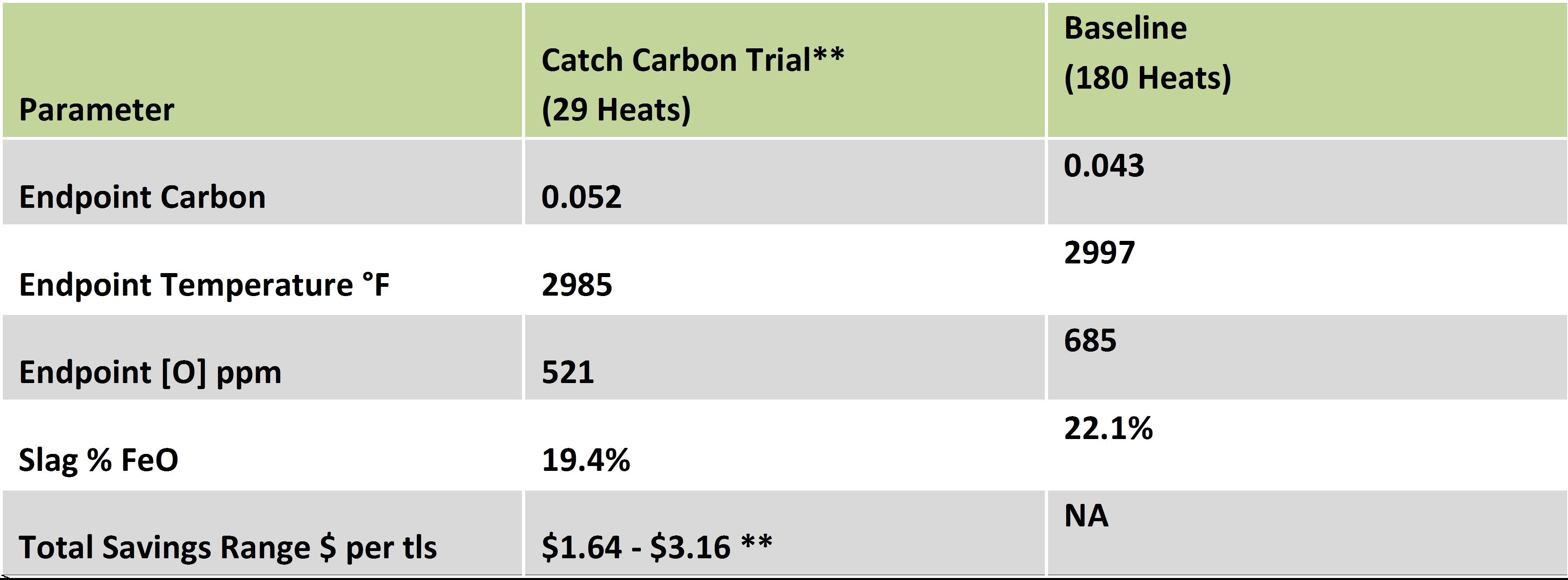

Catch Carbon Practice for Mid & High Carbon Grades; stopping a blow with precision at higher carbon levels is difficult; Tenova’s Catch Carbon Endpoint Detection system has demonstrated a 60% reduction in endpoint standard deviation on mid/high carbon grades thereby avoiding recarburization in the ladle, higher operating costs, higher tap oxygen levels and increased tap alloy consumption. Plant results confirm that using a 0.05% “Catch Carbon” practice instead of an 0.04% recarburization practice reduces endpoint [O] ppm and tap alloy consumption generating savings between $1.65- 3.15 per tls.

Complete Slag & Bath Chemistry prediction from start-to-end of heat: Tenova’s fundamental model predicts the evolution of both slag & steel chemistries from start-to-end of heat providing a valuable data base for i BOF® Digitalization advanced analytics & continuous improvement.

Improved Phosphorous Endpoint Control: Tenova’s Endpoint model predicts near-end of blow [P] for reduced phosphorous reblows