Technical data

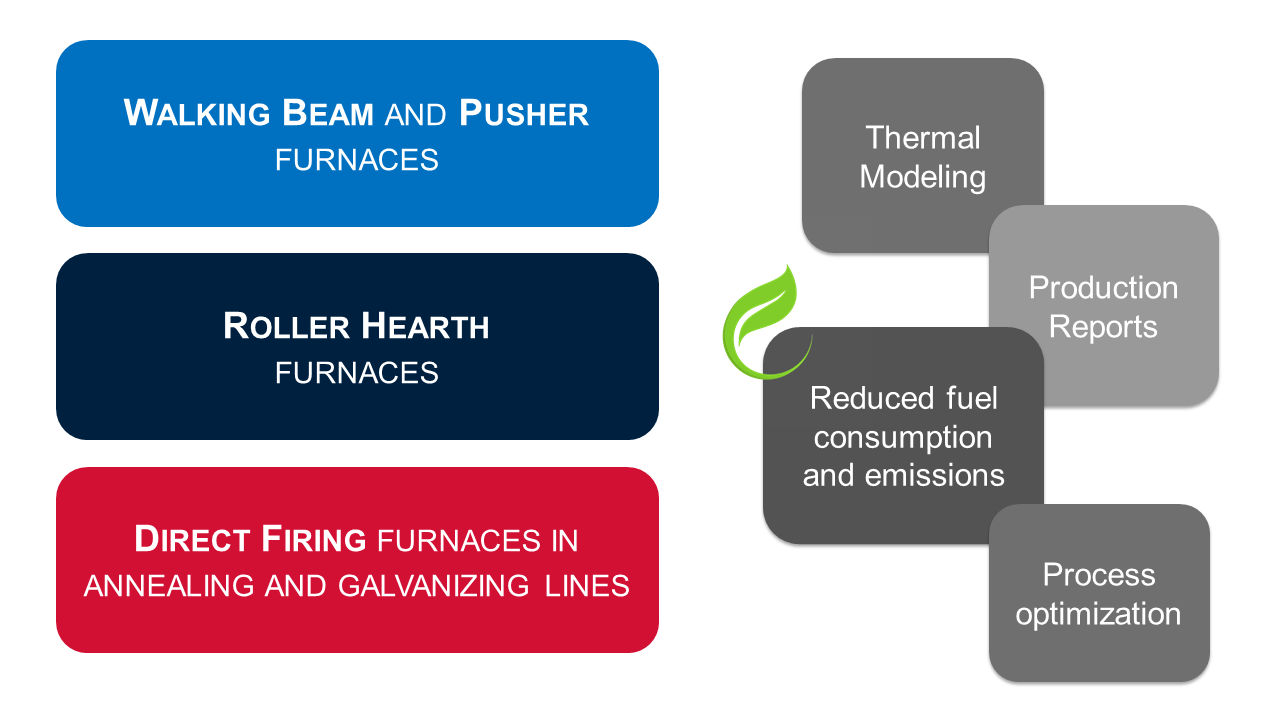

Tenova Sethlans’ application plants:

- Walking beam and pusher furnaces

- Roller hearth furnaces

- Direct firing furnaces in annealing and galvanizing lines

Tenova Sethlans’ functions for walking beam, pusher and roller hearth furnaces:

- Online thermal modeling for slabs and thin slabs, blooms, squared and round billets, beam blanks

- Predictive calculation of temperature setpoints

- Automatic management of mill and furnace stillstands

- Furnace pace rate modeling

- Adaptive feedback from the mill pyrometer

- Furnace thermal balance

- Production and thermal reports

Tenova Sethlans’ functions for direct firing furnaces designed for annealing and galvanizing lines:

- Online thermal modeling for strips

- Model predictive control of gas flow setpoints in both steady and transient state

- Adaptive feedback from the line pyrometers

- Production and thermal reports

In walking beam, pusher and roller hearth furnaces, Tenova Sethlans helps you achieve the following targets:

- A decrease in fuel consumption

- A consequent decrease in CO2 and NOx emissions

- A decrease in scale production with a direct effect on yield and overall productivity improvement.

- A precise control of the required dropout temperature through online modeling, predictive control and furnace pace rate modeling

Reduce fuel consumption by up to 5% through online modeling, predictive control and automatic stillstand management with a consequent improvement in CO2, NOx emission and scale formation. Further performance gains can be attained through the furnace pace rate modeling by granting the desired dropout temperature even during the transition from thin to thick load and by managing different furnaces feeding the same mill line. Worldwide references are available.

In direct firing furnaces designed for annealing and galvanizing lines, Tenova Sethlans helps you fulfill the following targets:

- Maximize the strip length achieving the required temperature targets

- An automatic adaption to variable line speed

Strip thick-thin and strip thin-thick transitions are optimized to get the maximized length of in-tolerance material through model predictive control. Line speed variations are absorbed through model predictive control giving the plant further performance gains.

After Sales Service & Support is available for any type of Tenova Sethlans application. Tenova Sethlans engineers can remotely connect to the system or help the customer improve the performance of the system on-site.