Technical data

Record Event Data (RED) is a tool developed by Tenova on the most up-to-date software technologies for time series analysis and data analytics.

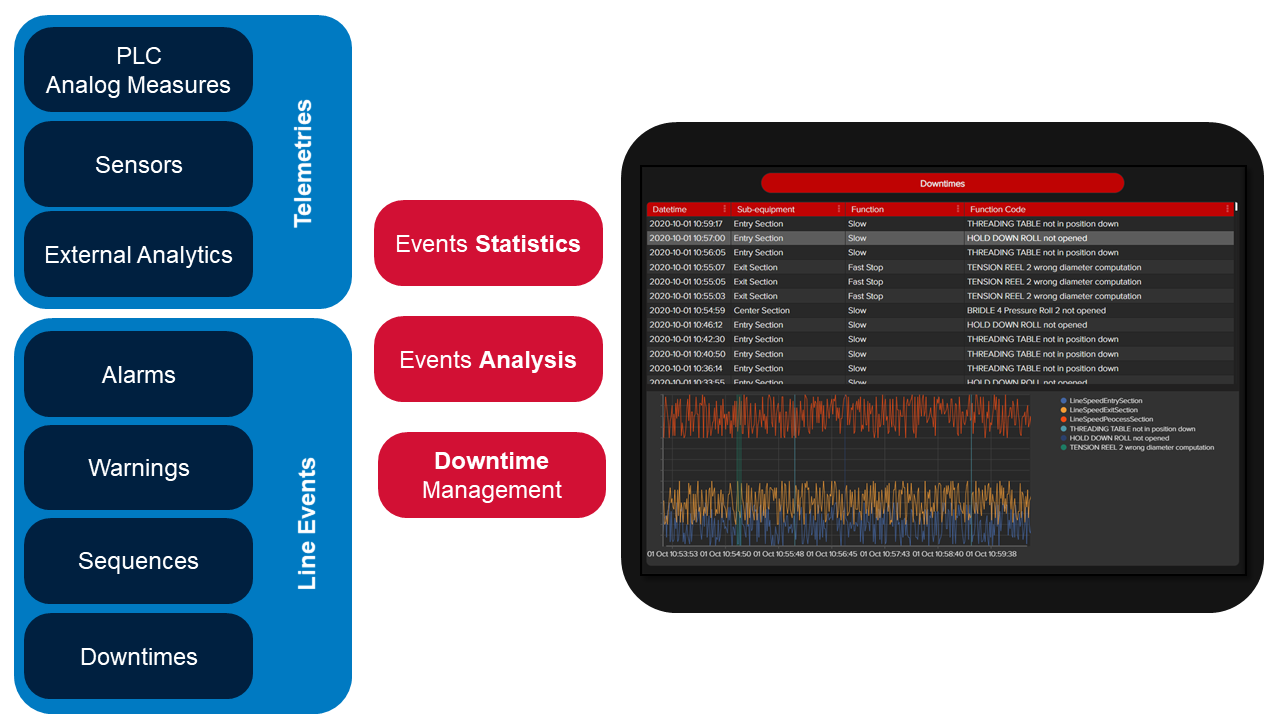

Data can be acquired from any datasources in the field, such as plant PLCs, sensors, soft-sensors or output of other analyses.

In addition, RED supports the management of line events such as alarms, warnings, sequences or downtime thanks to a decoding layer that lets its application in different scenarios or existing plants.

The power of this system is that the type and number of data collected can be expanded at any time.

When applied to a Processing Line or to a Reheating Furnace the PLCs are the main sources where data are generated and therefore where information is drawn.

It is seamlessly integrated into an edge computing context, where most of the data analysis and storage is done directly on-premises.

RED uses a large amount of heterogeneous data to create easy-to-follow summaries through tables and graphs.

To achieve these results, data is stored in specialized state-of-the-art databases.

Telemetry measurements, usually analog signals, are stored in time-series databases, making it easy to search for high-frequency data over large periods of time.

On the other hand, events occurring on the plant are saved in document-oriented structures that allow the addition of metadata for classification without predefined schemas.

Algorithms and functionalities integrated in RED allow a correlation between data that facilitate the technician's investigation through a simple interface.

RED's core software is based on container-based technologies to ensure flexible deployment and continuous updating in connected environments.

In fact, thanks to the optional connection to the Tenova IIoT platform it will be able to provide more complete analysis services to support maintenance. RED provides useful information to reduce downtime and suggests optimizations in the processes used to operate the line, thus improving the quality of the final product.