Safety

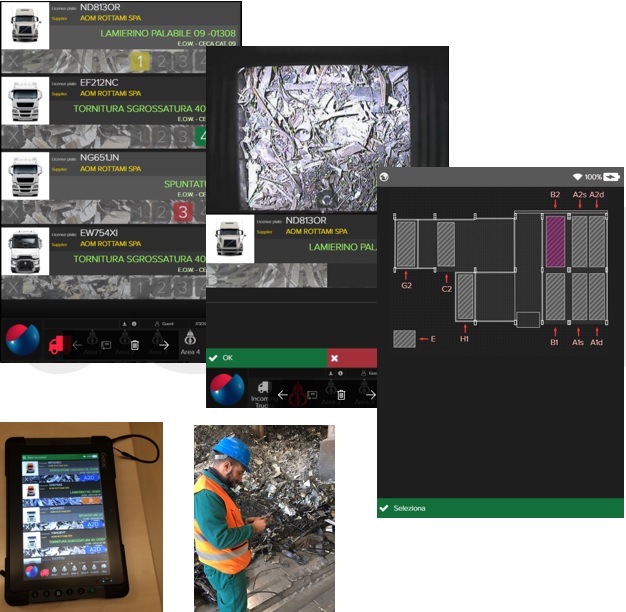

The operator at the scrap yard, in charge of receiving and classifying the materials delivered, is equipped with a rugged tablet, from which he receives all information relating to the material delivered.

By the tablet, the operator has the ability to immediately identify the trucks, by the receiving of the image related to the several trucks waiting for the material discharge operations.

This means that by clicking on the image of the single truck, all information related to the material delivered are immediately available to the operator.

Automatic EAF charging system:

This is an additional module also, dedicated to the full automatic bucket charge in EAF sequences.

The crane operator is located in main operator room and from here supervise to all operations.

The iSYM is able to:

- Drive the EAF charging crane automatically from the bucket car position to the EAF position.

- Run the EAF discharge operation, with the guarantee of center position on EAF and vertical movement in order to reduce splashing phenomena.

- Back bucket movement to backed car position.

The cranes control software is completed by an anti-swinging function, based on gyroscope sensor installed on crane’s hook.