Tenova TRGX regenerative and TRGSX self-regenerative flameless burners are the reliable technology for an immediate CO2 footprint reduction through improved combustion efficiency.

The current discussion about energy transition and the transformation of the metals industry into a climate-neutral sector by 2050 shall not overlook the impact of downstream furnace operations. In hot rolling processes, fossil feedstock is used as fuel and is responsible for the carbon footprint of final products between 100 and 250 kgCO2/tCS for billets and plates respectively.

In order to reach carbon neutrality, green fuels are needed; however, their profitability and availability still pose some obstacles to metals makers – consider for example the issues related to green hydrogen production and supply. In this context, the adoption of technologies that assure the highest possible level of fuel efficiency is crucial.

Tenova’s comprehensive approach to the sustainability of furnace combustion systems has led to the development and continuous improvement of regenerative and self-regenerative burners, launched onto the market in 2008. Since then, more than 500 regenerative/self-regenerative burners have been installed in several industrial plants all over the globe. The evolution of this technology provides our customers with HydrogenReady burners equipped with smart sensors for flexible operation.

Tenova’s expertise in regenerative burners

Tenova has a long tradition in leading-edge combustion technology and developed an interdisciplinary design process, which includes Computation Fluid Dynamics (CFD) modeling, industrial scale test and industrial applications.

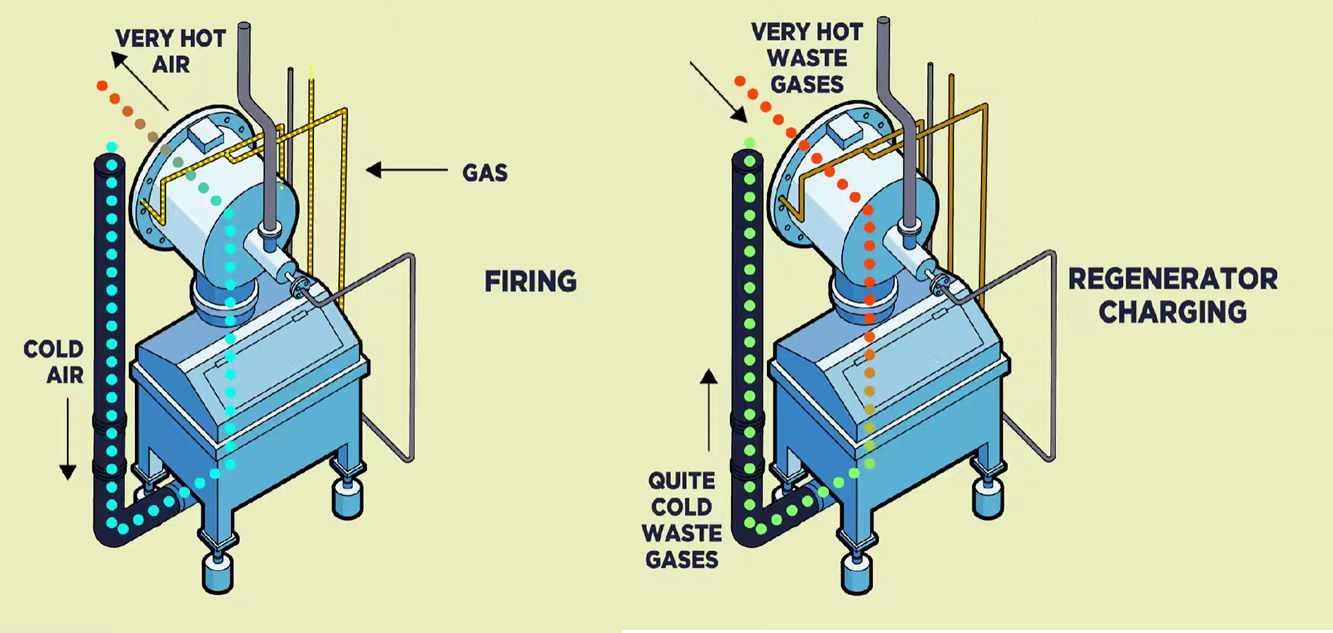

This virtuous approach was applied since the first developments of TRGX used in reheating furnaces, as well as of TRGSX self-regenerative flameless burners for heat treatment furnaces. The portfolio was then enlarged with the double regenerative burner TRGD, which is able to preheat both air and gas by using two different regenerators. The TRGD is suitable for equipment where gaseous fuel has a low net heating value, like Blast Furnace Gases. This represents a never-ending R&D process to furtherly enhance existing technologies and address the latest challenges for a sustainable industry.

The regenerative burner combustion systems represent an immediate solution to reduce CO2 emissions by about 10% compared to recuperative systems (currently the largest adopted technology on hot rolling mill and heat treatment lines). CO2 emission drops immediately independently from the availability of green fuel. However, Tenova’s regenerative burners are HydrogenReady: this means that whenever green hydrogen becomes available in the fuel network, end users can employ it, taking an additional step towards decarbonization – eventually achieving the zero-emission target.

In order to maintain burner performances at nominal levels throughout its life, Tenova has introduced the concept of SmartBurner. Its IIoT framework offers a complete set of process diagnostics, KPIs and KHIs that allow controlling the status of important process parameters (i.e combustion ratio, leakage of switching valves, combustion quality) and carrying out easier burner inspection and maintenance interventions.

The potential drawbacks (cost, complexity, control) posed by the regenerative burner technology have been overcome by Tenova through specific technological solutions such as correct material choice, burner design, control strategy, and overall furnace design. These significant improvements were made possible thanks to the extensive knowhow acquired over the course of more than forty years of experience.

Tenova’s regenerative flameless burners combine the lowest NOx emission level with high temperature combustion air preheating, while allowing a drastic reduction of CO2 emissions through high combustion efficiency. Hence, the sustainability of plants can be immediately improved even when green hydrogen is not yet available.

Want to know more?

Get in touch with our experts on the subject